PELA Commodities in Soroti is set to install Uganda’s first Aflatoxin removal machine (TOXI-SCRUBⓇ) in the coming weeks.

The machine which arrived in the country recently, is designed by Eye-Grain and supplied along with the grain handling equipment by Perry Engineering who are an authorised reseller of the TOXI-SCRUBⓇ system. It is assembled by Eye-Grain ApS, their local partner Grain and Toxin Solutions LLC (Uganda) and Perry Engineering who have also supplied the conveying and elevating system for the TOXI-SCRUBⓇ.

The machine will remove aflatoxins from high levels to 10ppb or less.It has different treatment programs and can be adjusted to make the necessary treatment to bring the contamination well below allowed levels. The machine can also eliminate not only Mycotoxins, but other biologic activity as well eg. bacteria, mites and insects.

The TOXI-SCRUBⓇ processing line can be tailored to any product in the Agro, Feed, Cereal supply chain. Including all types of grain, nuts, beans and cakes from the oilseed industry.

Aflatoxins is a type of mycotoxin produced by Aspergillus species of fungi, such as A. flavus and A. parasiticus. The umbrella term aflatoxin refers to four different types of mycotoxins produced, which are B1, B2, G1, and G2. Aflatoxin B1, the most toxic, is a potent carcinogen and has been directly correlated to adverse health effects, such as liver cancer in many animal species. Aflatoxins are largely associated with commodities produced in the tropics and subtropics, such as cotton, peanuts, spices, pistachios, and maize.

Uganda has lost over $38 million as a result of its inability to sell maize owing to aflatoxins (Shs140 billion). The Ugandan government is facing a significant budgetary load. Post-harvest grain handling activities are of poor quality, and many grain handlers are unaware of aflatoxins.

Maize is Uganda’s most important cereal crop, which is grown on both small and large scales and traded locally and globally by farmers. Because it provides opportunities for Ugandans across the value chain, the grain sub-sector is recognized as one of the most essential sectors for Uganda’s socio-economic transformation.

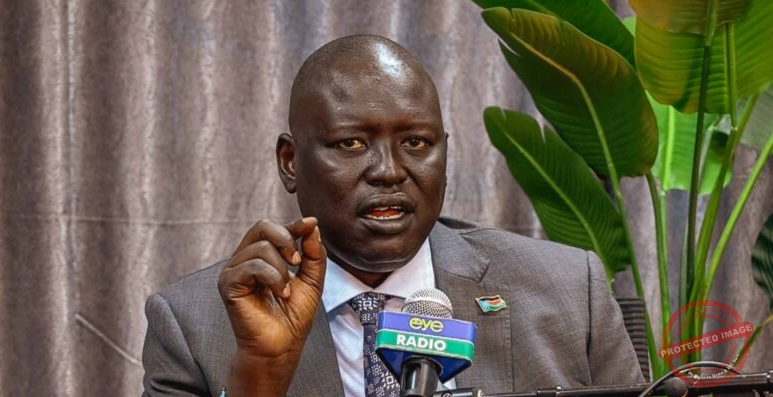

Commenting on the latest development, the PELA Commodities General Manager, Isaiah Langa said; “Uganda’s grain handlers have had a long-standing aflatoxin problem, but this is a step in the right direction to help enhance our yields and output. It will turn harmful maize or grain that cannot be exported or sold to reputable processors into a high-value product. We have already trained our team members on aflatoxin testing and they’re ready to start operating the machine.”

Perry Engineering are the designers and manufacturers of grain handling, cleaning, drying, and storage equipment and systems, small-scale flour mills, feed mills, and associated products. The company supports key industries such as agriculture (farms & commercial grain stores), feed mills, flour mills, flaking mills, waste and recycling, pelleting plants, aggregates, and biomass (woodchip, shavings & sawdust, grass and herbs). It has a wide range of products which include; continuous mixed flow driers, belt driers, moisture sensor systems, chain & flight conveyors, belt conveyors, belt & bucket elevators, screw conveyors & augers, aspirator pre-cleaners, twin trace conveyors, grain samplers and bins/silos.

Perry Engineering also offers key services such as plant layout and design, manufacturing, installation & commissioning, and a comprehensive after-sales service package for its customers.